Aprol

Process control applications range from small laboratory automation systems to large plants. The process control system offered by B&R offers significant scaling options that allow you to cover all areas of the application. It also provides support to system integrators and operators throughout the life of the system - from planning, creating and configuring libraries to commissioning and operation. Seamless integration and intuitive operation reduce installation times and ensure the highest level of machine and system productivity, while providing flexibility when changing products.

Key properties

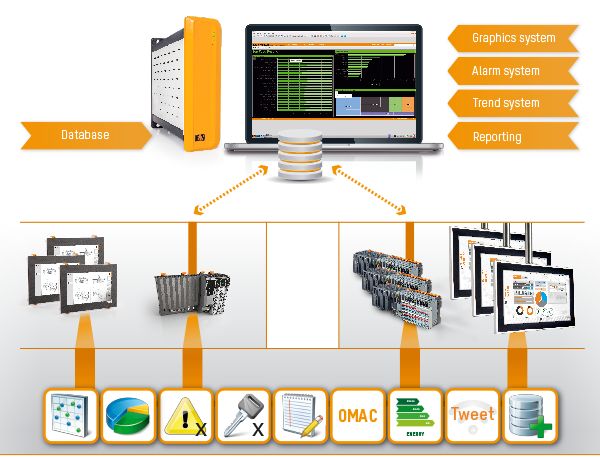

Aprol system

Expanding information

about the Aprol system

Standardized system components developed using an object-oriented programming language allow you to control entire systems. This reduces commissioning time and costs. Centralized project management enables very efficient and easy maintenance of entire systems. The whole system is also very secure.

Production automation includes, for example, automation of assembly lines, which can be used, for example, in the automotive or food industry. Centralized data acquisition from each module in the production line enables comprehensive online performance control. You can also monitor the flow of material or seamlessly monitor each completed production step.

A fully integrated process control system significantly reduces the amount of engineering on the one hand and at the same time reduces operating and maintenance costs during the entire system life cycle on the other hand. An integrated version control system speeds up system validation. Integrated alarm and trend systems ensure complete transparency without the need for additional expensive expert systems.

Centralized data acquisition from machines and equipment using standard protocols enables comprehensive online performance monitoring and visualization. Consistent archiving ensures long-term documentation and quality control. Integrated standard reports are the basis for convenient and detailed analysis of all process data for continuous improvement of production processes.

Integrated energy measurement modules supply all electrical values and quality assurance data. Data is collected from all energy sources (natural gas, oil, etc.) to ensure complete and automatic collection of all energy consumption. Energy management systems defined in ISO 50001 can be easily implemented by measuring and displaying consumption and cost data. Historical data allows for a detailed analysis of energy consumption, which makes it easier to identify cause and effect.

Online vibration measurement integrated in the I / O modules makes it possible to identify the mechanical condition of the machine and allows early detection of power reduction to prevent serious damage. Predictive condition-based maintenance reduces the number of unforeseen outages, keeping repair costs to an absolute minimum.

It is possible to regulate several interdependent physical values simultaneously, because the predictive model uses real process models. Operators can optimally compensate for failures and optimize the size of system components. Advanced process control modules can be used to optimize throughput and maximize efficiency.

Centralized data acquisition from machines and systems enables comprehensive performance monitoring and visualization. Long-term archiving ensures the ability to assess the quality of the production process. Integrated reports provide detailed analysis of all process data in order to optimize production processes. The combined display of ongoing data, alarms and events in TrendViewer makes it easy to track cause and effect.